From Raw Materials to Final Products: Behind the Scenes of Dry Carbon Fiber Manufacturing

In modern industries, dry carbon fiber products are highly sought after for their lightweight properties, exceptional strength, and superior aesthetics. From aerospace to racing and high-end automotive components, these products result from a meticulous and complex manufacturing process. Today, we invite you to step inside our factory and discover the journey of creating dry carbon fiber products.

Premium Materials: High-Quality Carbon Fiber Fabrics and Resins

Our process begins with selecting premium materials:

- Carbon Fiber Fabrics: High-performance carbon fiber fabrics with strength many times that of steel, yet only a fraction of its weight.

- Pre-preg Resin: Carbon fiber is pre-impregnated with a precise resin ratio to ensure uniformity and high performance.

These materials are the foundation of exceptional products, and we source only from the industry’s most trusted suppliers.

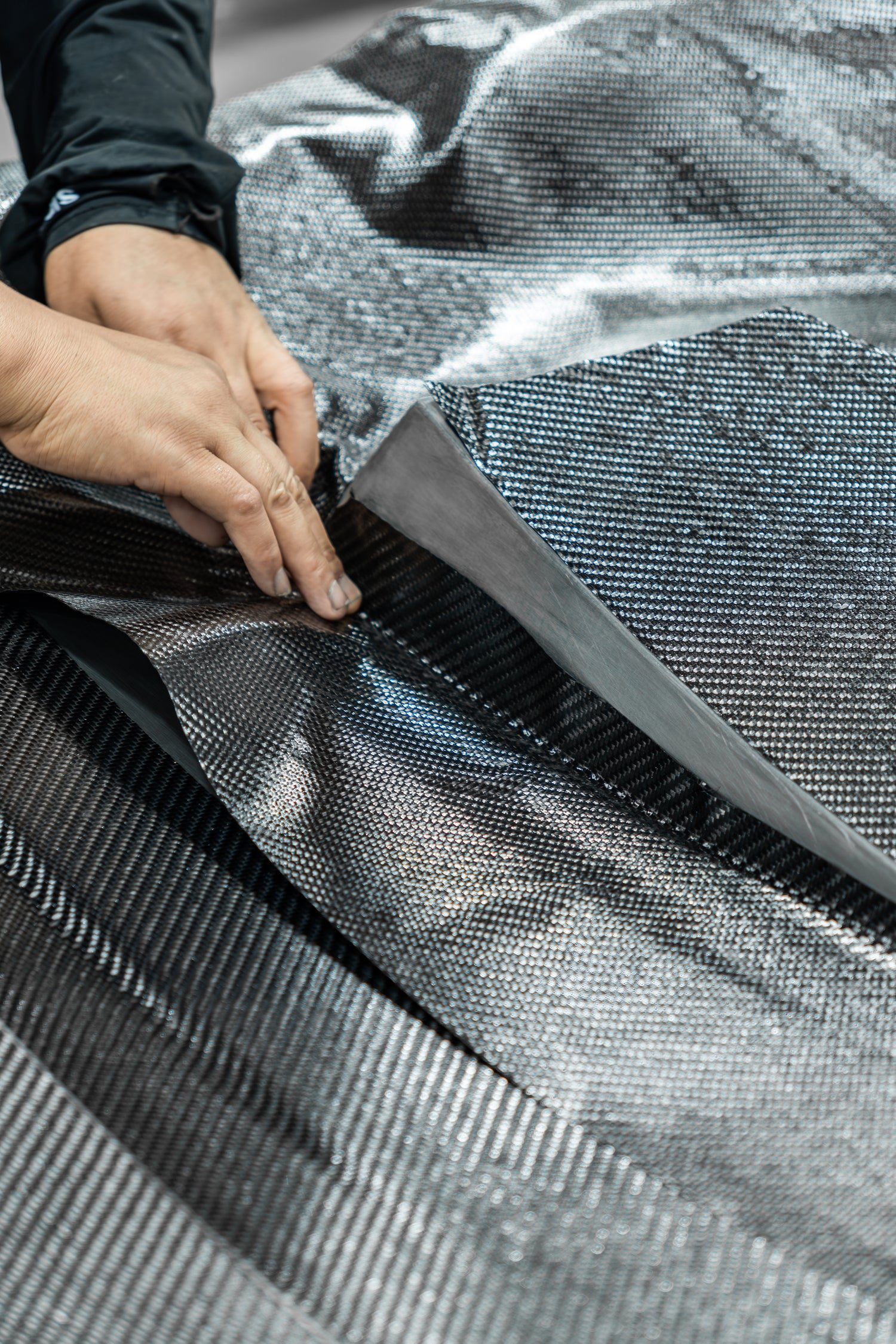

Precision Cutting: Shaping with Accuracy

Precision is key in carbon fiber production. Using advanced CNC cutting equipment, we meticulously shape the carbon fiber fabric to match design specifications, ensuring each part is prepared perfectly for molding.

Molding Process: Perfection Under Heat and Pressure

Our molding process employs vacuum bagging and autoclave technology:

- Layering: Carbon fiber fabrics are layered into molds and precisely arranged to meet design requirements.

- Vacuum Sealing: The layers are vacuum-bagged to remove air and prevent bubbles, ensuring maximum strength.

- High-Temperature Curing: The molds are placed in an autoclave, where heat and pressure bond the resin and fibers into a solid, three-dimensional structure.

This process ensures unmatched dimensional stability, strength, and lightweight performance.

Finishing and Detailing: Perfecting Every Detail

After curing, the carbon fiber parts undergo finishing:

- Trimming: Edges are trimmed with high-precision tools to meet exact specifications.

- Polishing: Surfaces are sanded and polished for a sleek, smooth finish.

- Coating (optional): UV-resistant or protective coatings can be applied based on customer requirements to enhance durability and aesthetics.

Rigorous Quality Control: Ensuring Precision and Reliability

Every product undergoes stringent quality checks before leaving the factory:

- Dimensional Inspection: Ensuring specifications are met precisely.

- Performance Testing: Verifying strength, heat resistance, and other key metrics.

- Aesthetic Inspection: Ensuring flawless surfaces that meet the highest standards.

Continuous Innovation: Advancing Carbon Fiber Manufacturing

Our factory prioritizes not only quality but also process optimization, embracing new technologies to enhance efficiency. Each carbon fiber product embodies our commitment to excellence and craftsmanship.

From production to performance, we strive to deliver outstanding carbon fiber products.

If you are a B2B customer looking for high-quality carbon fiber solutions—whether for bulk production or custom designs—we invite you to contact us. Let us collaborate to create the perfect carbon fiber solutions tailored to your needs.

We look forward to working with you!

Contact Information

BIMMER BOOSTS

Email: info@bimmerboosts.com

Phone Number: 8057083946